Asia-Pacific is Projected to Be the Prime Revenue Generator in the Industrial Packaging Market Through 2021

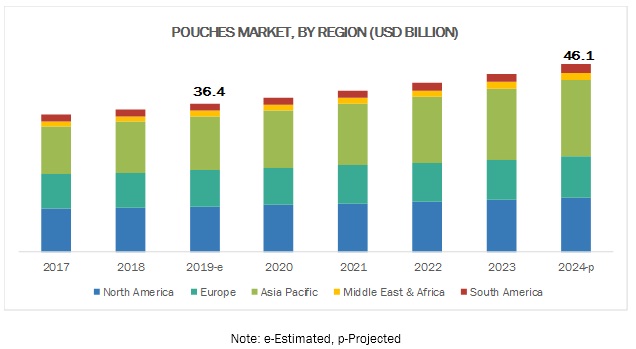

The Market for Industrial Packaging is projected to grow from USD 54.94 Billion in 2016 to reach USD 93.28 Billion by 2026, at a CAGR of 5.4%.

Browse 111 market data tables and 48 figures spread through 168 pages and in-depth TOC on “Industrial Packaging”.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=10341323

The sacks pack type segment is expected to gain maximum traction during the forecast period

Sacks are highly preferred due to its characteristics such as lightweight and easily movable; it is used at sites such as automotive, construction, manufacturing, and food & beverages. The sacks segment accounted for the largest share in 2015; and it is projected to grow at the highest CAGR between 2016 and 2026. The sack segment is projected to remain the largest, owing to easy usability and handling of sack packaging.

The chemical & pharmaceutical segment is projected to grow at the highest rate during the forecast period

The industrial packaging market is segmented on the basis of end-use industry into transportation & logistics, automotive, construction, chemical, and food & beverages, and others. The chemical & pharmaceuticals segment accounted for the largest share in 2015; this is projected to grow at the highest from 2016 and 2026. The CAGR over the next ten years is projected to be higher, owing to the increasing use of chemical in the manufacturing industry and other industrial applications.

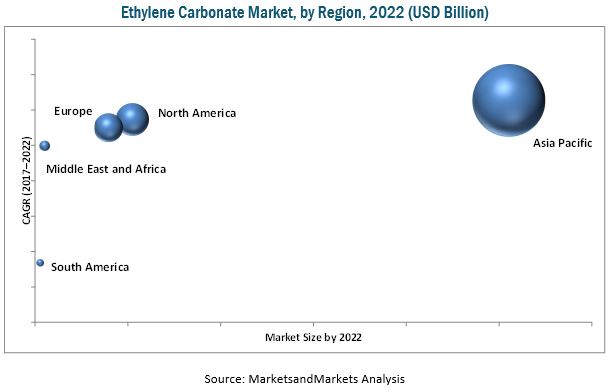

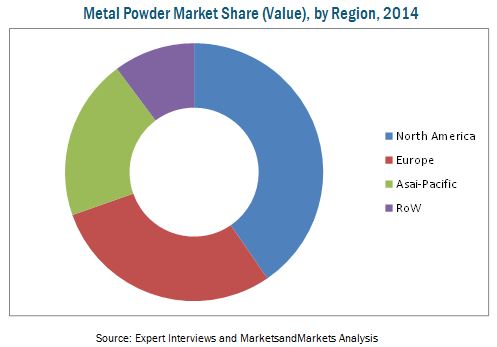

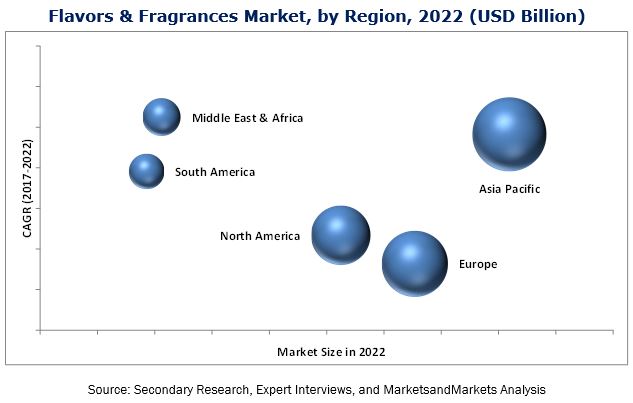

Asia-Pacific to play a key role in the market for industrial packaging

On the basis of key regions, the market for industrial packaging is segmented into North America, Europe, Asia-Pacific, and the Rest of the World (RoW). The low labor costs, excellent industrialization, a huge scope for FDI, emerging economic conditions, stable government scenarios, and an excellent hold on industries such as construction, automotive, and chemical have played a crucial role in the growth of the market for industrial packaging in the Asia-Pacific region.

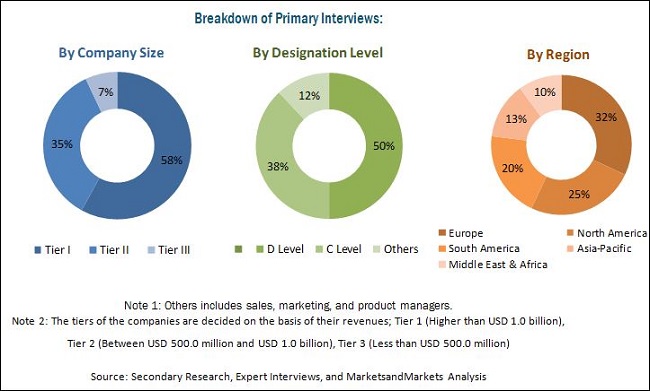

Strategies such as mergers & acquisitions and agreements & expansions were largely adopted by most of the players in this market. Companies such as Grief Inc. (U.S.), Mondi Plc (South Africa), Amcor Limited (Australia), WestRock (U.S.), International Paper Co. (U.S.), Bemis Company Inc. (U.S.), Orora Group (Australia), Mauser Group (Germany), Sigma Plastics Group (U.S.), and Wuxi Sifang Drums Company (China) were the key players who adopted these strategies to expand their businesses globally by investing in the establishment of manufacturing facilities and technical service centers in various regions.

Get 10% Free Customization on this Report @ https://www.marketsandmarkets.com/requestCustomizationNew.asp?id=10341323

Companies such as Grief Inc. (U.S.) is one of the largest in terms of quality, sales, and profitability. It has begun to rebalance manufacturing network, lower structural operating costs and sell underperforming operations, which have affected 26 operating facilities in rigid & flexible packaging & services globally.

For more Info Visit Blog: https://chemicalsresearchmarket.wordpress.com/blog/

About MarketsandMarkets™

MarketsandMarkets™ provides quantified B2B research on 30,000 high growth niche opportunities/threats which will impact 70% to 80% of worldwide companies’ revenues. Currently servicing 7500 customers worldwide including 80% of global Fortune 1000 companies as clients. Almost 75,000 top officers across eight industries worldwide approach MarketsandMarkets™ for their painpoints around revenues decisions.

MarketsandMarkets’s flagship competitive intelligence and market research platform, "Knowledgestore" connects over 200,000 markets and entire value chains for deeper understanding of the unmet insights along with market sizing and forecasts of niche markets.

Contact MarketsandMarkets™:

Mr. Sanjay Gupta

MarketsandMarkets™ INC.

630 Dundee Road

Suite 430

Northbrook, IL 60062

USA: 1-888-600-6441

sales@marketsandmarkets.com

The

The

The

The